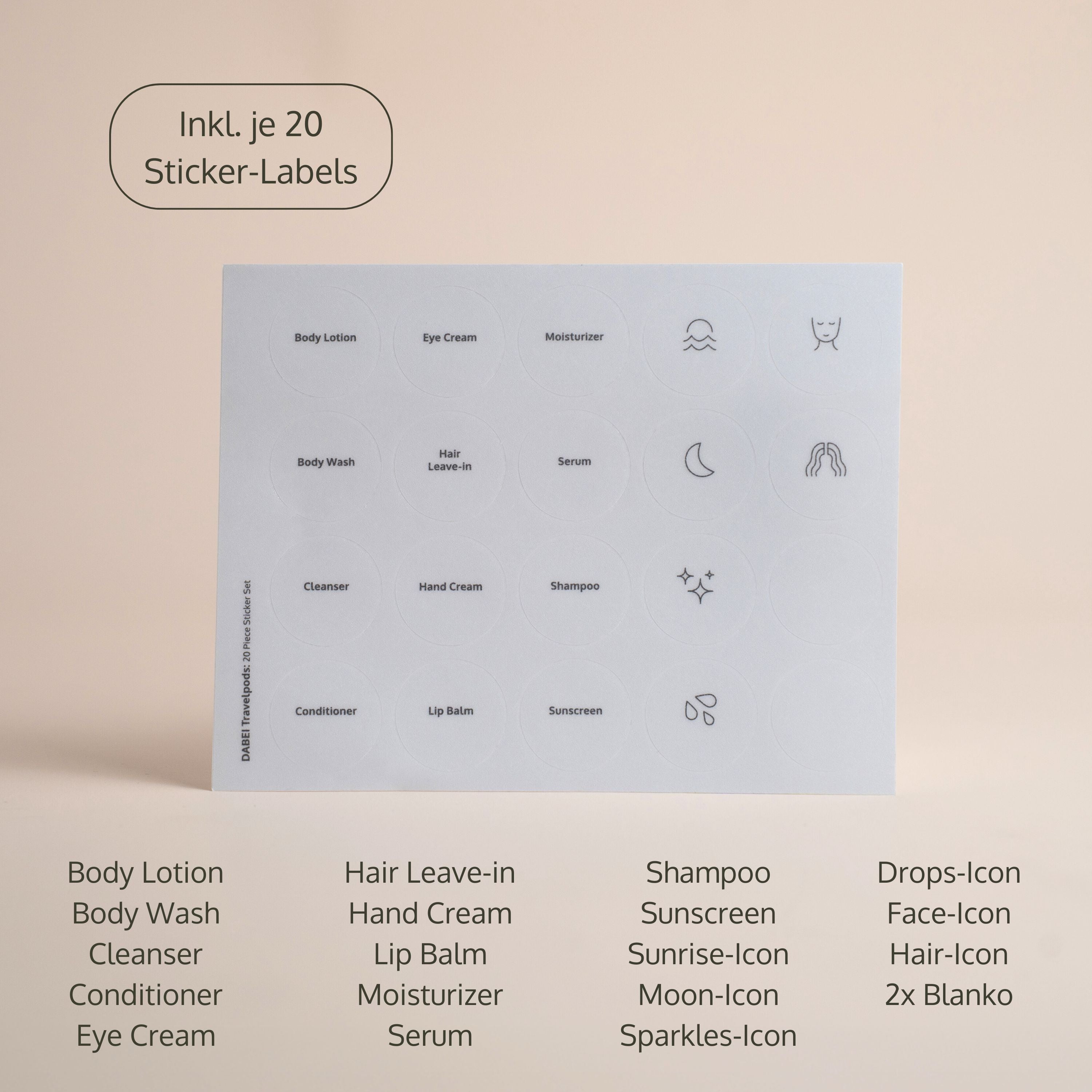

Our journey to develop the DABEI Pods was challenging, exciting and full of learning moments. Over several months, we tested around 20 different designs and more than 100 3D-printed prototypes - with our 3D printer running for over 300 hours in our apartment. We tried out countless shapes, functions and connection options to finally find the system that combines everything that is important to us for this product category: different sizes, a practical pump, easy cleaning, playful connections, product safety, and recyclability—these are the features that set our Travelpods apart.

Why is the development of products like the Travelpods so complex?

Four different sizes, many individual parts

Each of our 13 plastic components requires its own production tool - and all parts have to work together precisely. This makes for a difficult coordination process.

Extremely tight tolerances

To ensure that everything fits perfectly and stays sealed, some parts have to be manufactured to an accuracy of a few hundredths of a millimeter. This requires maximum precision at every stage of production.

High requirements for the materials

Our pods don't just have to look good, they also have to be REACH-compliant, chemically resistant and break-resistant. This severely restricts the choice of materials - and makes production much more challenging.

Concept and Design

03/2024 - 05/2024

Over the course of several months, we designed various concepts and printed them as 3D models to test their usability and manufacturability. Our goal was to create travel containers that were not only functional but also aesthetically pleasing. Every detail - from the different sizes to the magnetic connections - was developed with your needs in mind.

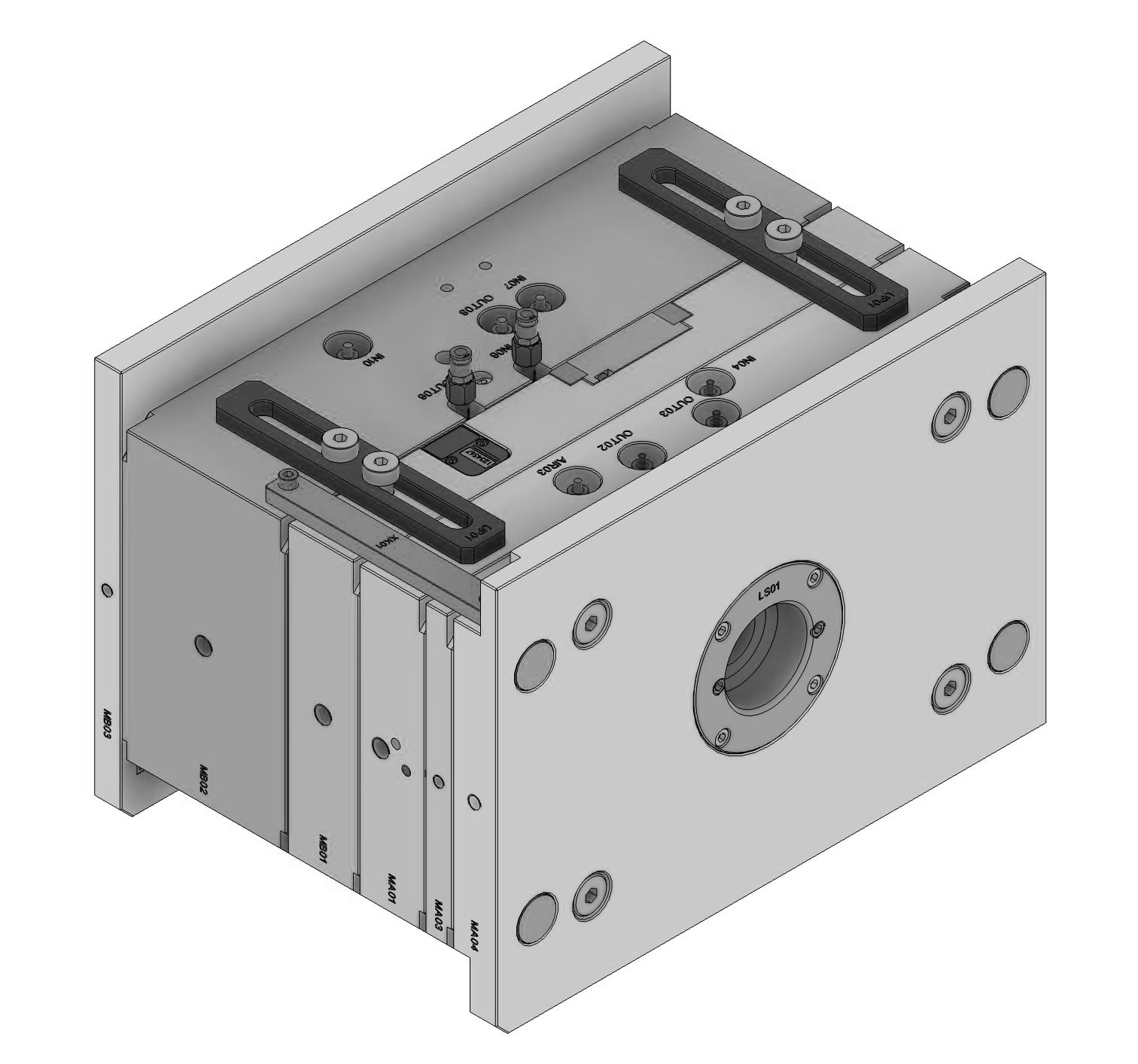

Design for Manufacturing and Design of Production Tools

06/2024-11/2024

Once the concept was finalized, we worked closely with our manufacturing partner to prepare the production process. Our focus was on designing the pods for production and developing production tools that would enable consistent, precise and high-quality production.

Material Selection and Testing

11/204-04/2025

The choice of materials was a central point in our development. We looked intensively at various options, carried out countless tests and finally selected materials that not only meet the strict EU safety standards, but are also robust and recyclable.

Production and Quality Control

04/2025-07/2025

After months of intensive development and thanks to the support of our successful Kickstarter campaign, we were able to go into production for the first time in summer 2025 and put our production tools into use. In the subsequent quality control process, the pods were carefully checked - from tightness and accuracy to surface quality.